Imerys Minerals is a French stock exchange corporation and the biggest white pigment supplier in the world. The corporation operates in 50 countries, owns 230 industrial objects and has over 16 000 employees. The annual turnover of the Group is 4,4 billion Euros. For a reliable and efficient production process, the company has been cooperating with Ontec Oy for a long time.

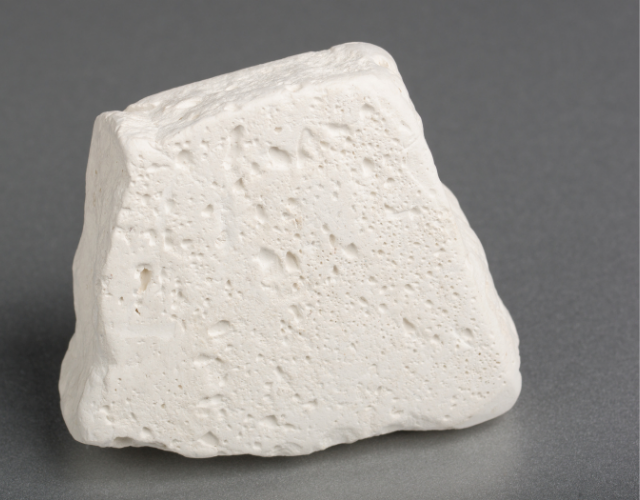

Imerys Minerals manufactures everything from paper industry special coatings to car parts, from toothpaste to cosmetics ingredients and from firebricks to natural minerals for food. The top Imerys minerals are kaolin, bentonite, calcium carbonate, diatomite and perlite.

Imerys Minerals slurry plant in Kotka, Finland produces currently 40 000 ABS dry tons of kaolin slurry annually. The host of the visit local Plant Manager Jussi Pitkänen, tells that most of the production is used in the paper industry for paper and cardboard coating.

Quality control at the plant is important and is done constantly.

Efficiency comes from trustworthy automation

Imerys Minerals has been collaborating with Ontec closer to 20 years so far. Ontec has been heavily involved in developing kaolin slurry plant process automation. ”Optimising the number of our employees has been mostly possible due to trustworthy and well-designed automation. It has been a pleasure to develop it together with professionals of Ontec. Things work as they should. We have been able to rely on Ontec year after year. I warmly recommend Ontec for delivering process automation control systems for demanding industrial objects”, tells Plant Director Jussi Pitkänen.

The cooperation has been pleasant for Ontec as well. Working with a customer who is exceedingly familiar with the technical details of the production process has made communication easy.

From summer worker to Plant Director

Pitkänen began his career in Kotka plant in the summer of 1987, when the plant was just starting its operations. His initial plan was to stay for four months, but he ended up working in practically all departments of the factory, in managerial roles, and finally became the Plant Director. Pitkänen still considers himself to be a man of action, rather than an administrator. Whenever his managerial duties allow, you are most likely to find Pitkänen in the production hall with his hands in the dirt. Dirt, in this case, being literally clay (kaolin).

At the plant, everywhere you look you see the employees working relentlessly. Pitkänen is genuinely proud of his team and gives thanks to his employees’ attitude and professionalism. Need be, the team pulls together and works as long as it takes to fulfil an urgent customer order.

Special coatings for paper and paperboard industry

Despite global paper and paperboard product market decreasing by 5% annually, Imerys Minerals trusts the market also in the future. This trust is based on continuous product development by the company. Imerys Minerals is confident their specialised patented products will continue to be in demand also in the future.