Air travel is always carefully planned, whether it is for passenger or cargo traffic. In reality, the air journey itself is only a small part of the process that is running as an unbroken chain of actions during each flight. Ontec Oy is part of this chain, where we contribute to ensuring the smooth flow of fuel transports, the safety of air traffic and the security of supply in Finland, starting from the refinery to the tip of the aircraft wing.

This is the first article in a series that discusses the process behind the scenes of air transport from Ontec Oy’s point of view.

The starting point of the journey is the refinery where jet A1, more commonly known as aviation kerosene, is produced. In such a potentially explosive environment, where a dangerous substance may be present in liquid form as well as in the form of an invisible gas, special care must be taken.

OntecRTA – a safety and access control system ensures that access to an area or space is always based on up-to-date information. The RFID tag contained in the unique ID card is the key to all systems and identifications during the upcoming trip, starting from the office door when the driver arrives at the refinery site. The ID card reader is an Ethernet-enabled terminal. When displaying the card, the system checks the driver’s access rights in the cloud service. These permissions can be remotely managed in real time and on a state-by-space basis. A time limit can also be set in the system, above which an automatic alarm is triggered.

OntecRTA – BENFITS

- Improved safety – automated alarms when time limits exceeded

- Current information at all times who is located in your premises and why

- Permit-to-work and qualifications always up to date – higher environmental and operative safety

- Fast detection of everyone on site in cases of emergency

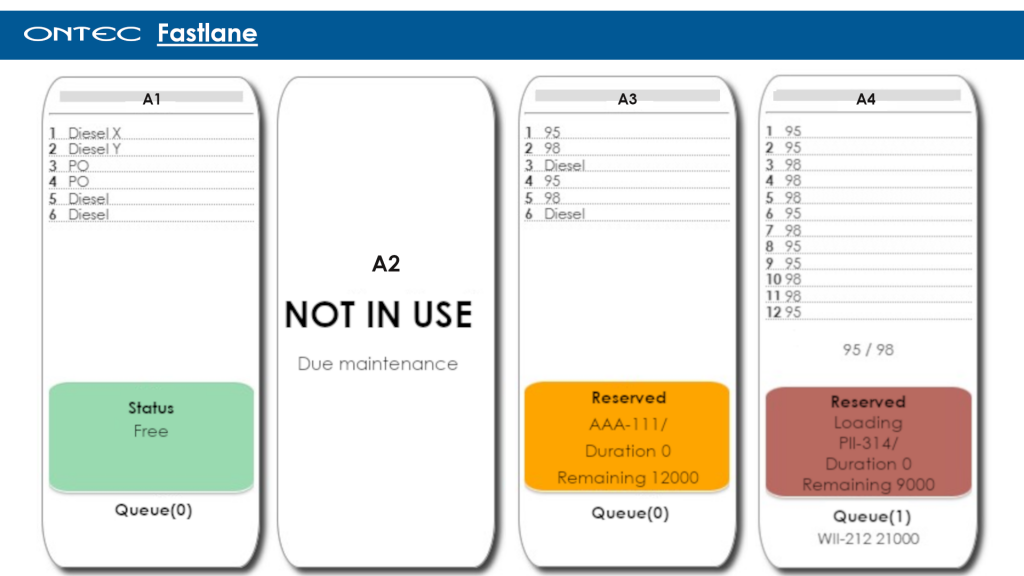

In the office, the driver’s task is to use the OntecMilo system to activate the order that he has come to pick up. The intelligent system suggests to the driver, taking into account the contents of the load and the queuing situation, the best option for the loading location. Drivers waiting for their own loading shift can see in real time on the OntecFastLane (pictured below) screen the loading situation, the order of queuing and, for example, ongoing maintenance operations. Only when it is your turn to drive tankers to the loading area, this way the congestion in the loading area is under control and the level of safety is improved.

BENEFITS – Ontec FastLane

- Drivers and operators have real-time, comprehensive information on the operation of the area and equipment, as well as on the product range.

- The safety management of the loading area is made easier when there are no extra drivers and vehicles.

- Free loading platforms are clearly visible, which speeds up operations, reduces traffic jam and wasted time.

- Queuing to loading platforms is systematic.

- The loading queue is flexible, drivers can prepare to move to the loading area when they see the situation of the previous load in real time.

- Maintenance work and changes in the product range are visible in real time for both drivers and operators, not unnecessary traffic on closed loading platforms.

- The system promotes the process in a multi-level way and drivers can return to the roadside faster.

The next part of the series of articles will focus on actions at the refinery, refueling the tanker truck, and the journey to the airport continues.