In the third part of the series, we operate in airport conditions, where safety is the most important thing in both passenger and cargo traffic. Security at the airport is regulated by the common rules of the EU countries, the implementation of which is supervised by Traficom in Finland. Traficom also determines the necessary measures to improve safety for operators there.

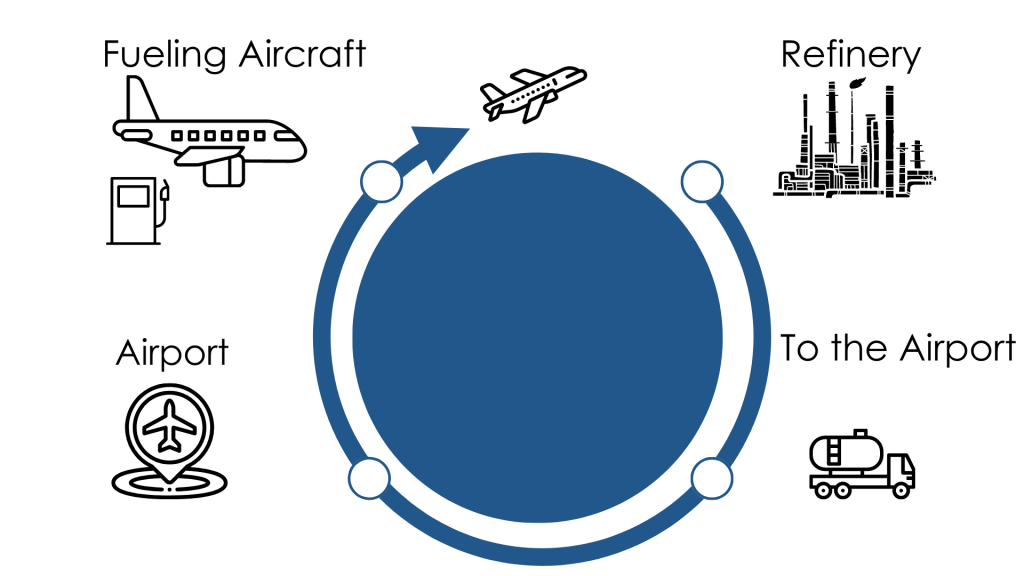

In order to enter the airport area, the driver of a tanker truck that has departed from the refinery must identify himself at the gate with a personal ID card to the OntecRTA reader. With the help of a individual RFID tag, access rights to the area can be managed in real time and by space with the help of a cloud service. Before unloading JET A1, aviation kerosene into the tank, the driver takes a sample to ensure the quality of the liquid in accordance with the requirements of the JIG standard. The sample taken is analyzed with a device designed for airport conditions and the result is recorded in the OntecJetAir JIG-compliant quality management system. The OntecJetAir system compares the quality of the batch with the given limit values and gives the driver permission to unload the aviation kerosene into the tank. When unloading fuel, the driver also checks the quantitative correspondence between the quantity loaded from the refinery and the cargo unloaded into the airport tank. After that, the driver returns to the refinery where our journey began, but the JET A1 continues its journey from here.

At the airport, the transportation of aviation kerosene to the aircraft is carried out by a fuel delivery truck designed for this purpose. The personnel responsible for refueling the aircraft record in the OntecJetAir system the information related to the event – as well as the information required by the JIG standard, among others. In the OntecJetAir system, the batch identifier and the MID-approved measurement result that followed the fuel batch from the refinery continue to travel with the aircraft until the last drop.

JIG compatible control systems

OntecJetAir is a JIG compatible control system for maintenance management of vehicles, procedures and equipment related to aviation fuel handling at airports. Several airports can be integrated into the system so that all data to be seen in a single application. OntecJetAir system can be used for monitoring inspection history, as well as for recording and reporting deficiencies identified. Specific requirements related to Jet A1 handling have been considered.

OntecJetAir maintenance control system features:

- Automatic measurement of water content in a sample

- Tank measurements

- Automatic sampling

- Differential pressure monitoring

- Consigment notes

- Gas concentration measurements

- Weather stations

- Lighting

- Firewater system

- Alarm and event history

All is done in accordance with the Joint Inspection Group JIG quality standards. The system reminds the user of unfinished inspections and sends automatic requests for correction on the basis of the entries made. The system can also be used for recording the repair history and scheduled maintenance, as well as for producing reports required by the authorities. Entries can also be made directly from the refuellers.

Ontec systems from the refinery to the tip of the aircraft wing

Ontec product line offers advanced control systems, as well as software. All products can be integrated with each other and various kinds of industrial systems. From these modules you can easily create a modern and reliable MID approved and ATEX certified. In a series of articles, we covered the JET A1 process, the journey of aviation kerosene from the refinery all the way to the tip of the aircraft wing. During this trip, in addition to OntecJetAir, we got to know the following Ontec products:

OntecFastLane

Intelligent vehicle- and loading platform control system

OntecFastLane is a fully automated vehicle and distribution terminal control system developed for truck loading terminals. The system tells the driver where to drive, when to prepare and when his shift will come.

OntecMilo

Liquid loading system

OntecMilo is a perfect solution for handling and loading liquids such as fuels, LNG and different chemicals. The system is suited for handling liquid bio-based fuels like SAF (sustainable aviation fuel) and for the treatment of other biofuels and mixtures.

OnatexMID

MID MI-005 and ATEX approved liquid measuring system

OnatexMID is a measuring system complying with the European Union Measuring Instruments Directive (MID 2014/32/EC). It is MID MI-005 approved dynamic measuring system for measuring liquids other than water.

OntecRTA

Real-Time-Acces -security and safety control system

The system ensures that people’s access to the area or space is always based on up-to-date information.

OntecRTM

Real-Time-Maintenance software

The system compiles the operating hours automatically. Entries can also be added or viewed from the automation system control room.

OntecRTS

Real-Time-Service -support package 24/7

Our OntecRTS Real-Time Service maintenance and service package can be customized according to the customer’s needs.